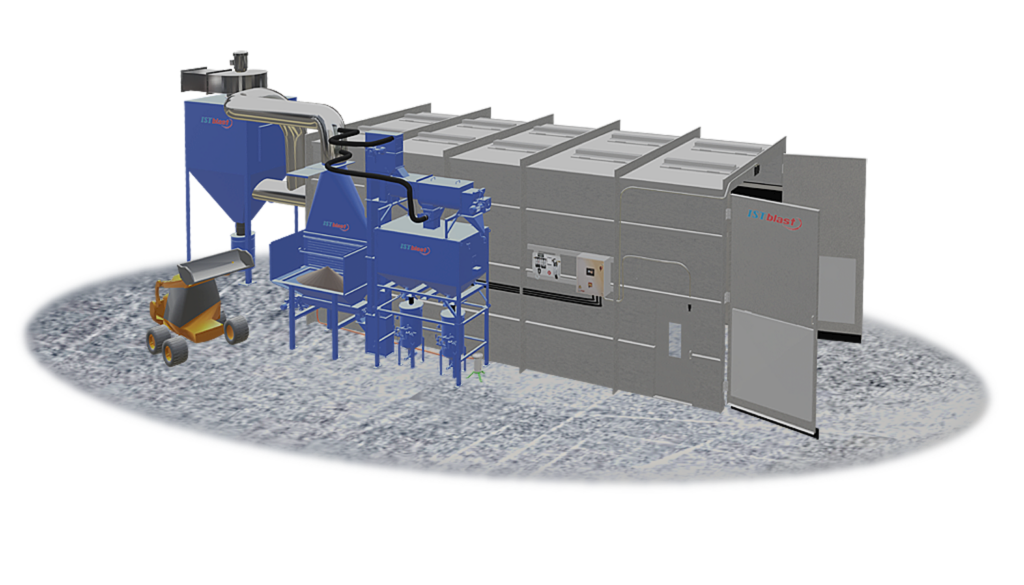

The evolution of blast booth technology is rapidly transforming the surface preparation industry. As industries seek more efficient and environmentally friendly methods, innovative designs in blast booths are leading the way. This blog delves into the future of blast booth technology, highlighting advancements that are setting new standards in the industry.

Enhanced Efficiency and Productivity

Modern blast booths are engineered to optimize efficiency and productivity. Today’s designs incorporate automated systems that significantly reduce manual labor and operational time. These systems ensure consistent quality and uniformity in surface preparation, which is crucial for industries relying on precise finishes. The integration of advanced robotics and automated abrasive recovery systems minimizes downtime and maximizes throughput, making blast booths indispensable for high-volume production environments.

Eco-Friendly Solutions

Sustainability is a major focus in the development of new blast booth technology. Manufacturers are increasingly incorporating eco-friendly features to meet stringent environmental regulations. Dust collection systems and filtration technologies are now standard in many blast booths, effectively capturing and containing particulate matter. Additionally, the use of recyclable abrasives reduces waste and minimizes the environmental impact. These green innovations not only help protect the environment but also improve workplace safety and health.

Versatile Applications

The versatility of modern blast booths extends beyond traditional surface preparation. With customizable configurations, blast booths can cater to a wide range of industries, including automotive, aerospace, marine, and construction. Whether it’s a small-scale paint spray booth for intricate parts or a large blast booth for heavy equipment, manufacturers are designing solutions that meet diverse needs. The adaptability of these booths ensures that they can handle various materials and substrates, from metal and plastic to wood and composites.

Cutting-Edge Control Systems

Advanced control systems are at the heart of innovative blast booth technology. These systems provide operators with precise control over blasting parameters, ensuring optimal results. Touchscreen interfaces and programmable logic controllers (PLCs) allow for easy adjustments and monitoring of the blasting process. This level of control enhances accuracy and repeatability, reducing the risk of errors and improving overall efficiency. Furthermore, real-time data monitoring and reporting capabilities enable proactive maintenance and troubleshooting, minimizing downtime and extending the lifespan of equipment.

Safety Enhancements

Safety is a paramount concern in the design of modern blast booths. Innovations in safety features are reducing the risk of accidents and injuries. Enclosed blast booths with secure access controls prevent unauthorized entry and ensure a controlled environment for blasting operations. Enhanced ventilation systems and noise reduction technologies contribute to a safer and more comfortable workspace. Additionally, emergency stop systems and safety interlocks provide immediate shutdown capabilities in case of malfunctions or hazards.

Improved Cost-Effectiveness

Investing in a state-of-the-art blast booth is becoming increasingly cost-effective. Advanced designs focus on reducing operational costs through energy-efficient systems and durable construction. The integration of energy-saving technologies, such as LED lighting and efficient compressors, lowers utility expenses. Moreover, the robust build quality of modern blast booths reduces maintenance and repair costs over time. For businesses looking for a blast booth for sale, these cost-saving features make a compelling case for upgrading to newer models.

The Future of Blast Booth Manufacturing

As technology continues to advance, the future of blast booth manufacturing looks promising. Innovations in materials science and engineering are paving the way for even more durable and efficient blast booths. The incorporation of smart technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), will further revolutionize the industry. IoT-enabled blast booths can offer predictive maintenance and remote monitoring capabilities, enhancing operational efficiency and reducing downtime. AI-driven systems can optimize blasting processes in real time, ensuring consistent and high-quality results.

Concluding Remarks on the Evolution of Blast Booth Technology

The landscape of blast booth technology is undergoing a significant transformation. With a focus on efficiency, sustainability, versatility, and safety, modern blast booths are setting new benchmarks in the industry. As manufacturers continue to innovate and integrate cutting-edge technologies, the future holds exciting possibilities for further advancements. For businesses looking to invest in a blast booth or upgrade their existing equipment, the latest innovations offer compelling benefits that can enhance productivity, reduce costs, and improve overall operational efficiency.